From initial transformer lamination production in 1927 to serve the infant radio industry thomas skinner s ei transformer lamination operation led the way pioneering large three phase wide window and thin gauge laminations.

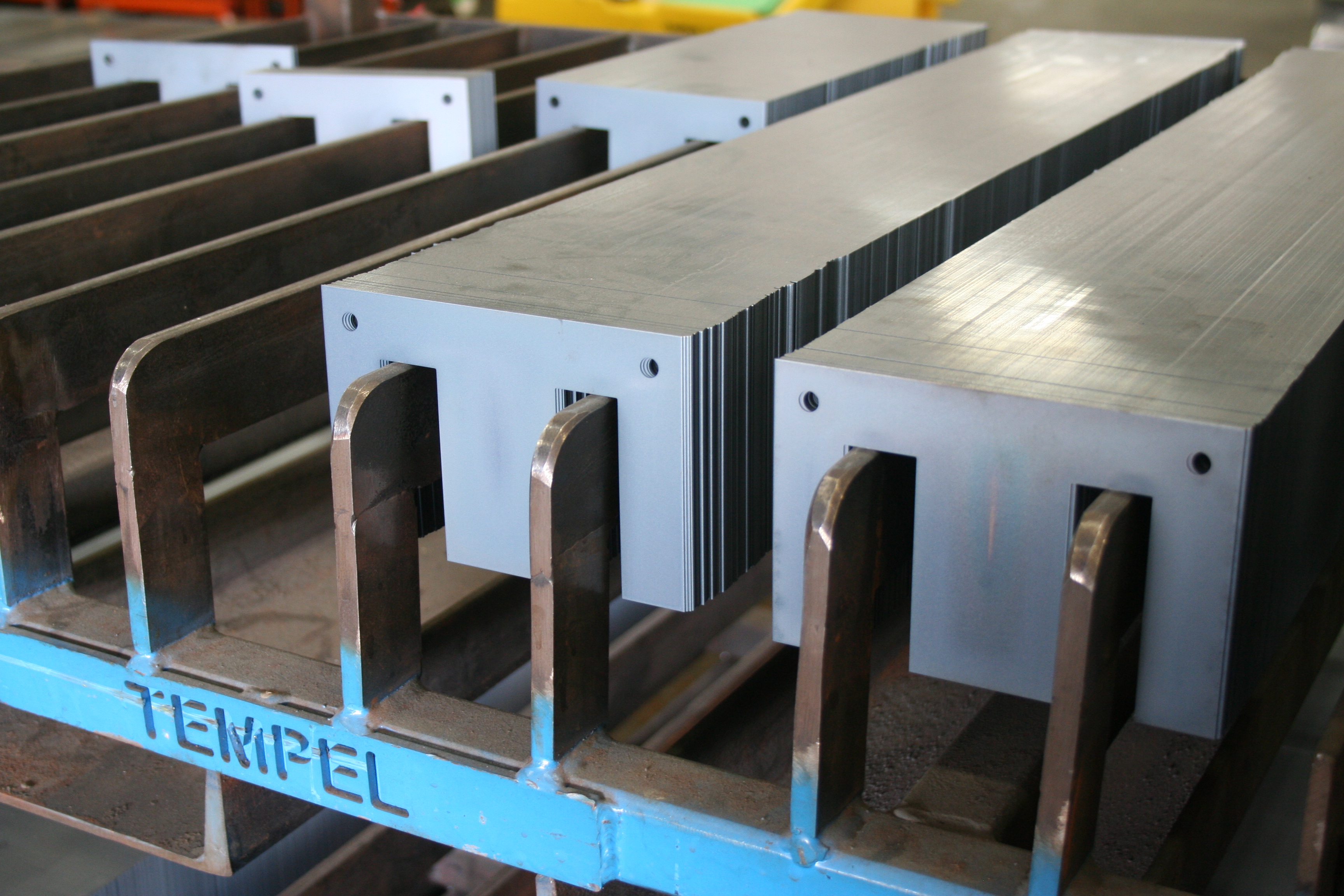

M6 steel laminations.

These core laminations are required to be cut from special steel called as cold rolled grain oriented electrical steel or popularly known as crgo.

The crgo is a special quality of steel which have a special grain surface and comes in a thickness of 0 23 mm 0 27 mm 0 30 mm 0 35 mm.

Generally called m3 m4 m5 m6.

Electrical steel lamination steel silicon electrical steel silicon steel relay steel transformer steel is an iron alloy tailored to produce specific magnetic properties.

We also offer thin gauge low loss grades for special applications with technical support to better understand customer needs and recommend most cost effective.

We are the market leaders in jencore unicore design and offer the latest advancements in material technology.

Due to substantially higher material cost thin electrical steel is used primarily for high performance and high frequency applications.

Manufacturer of transformer lamination m6 transformer lamination crgo transformer lamination m3 transformer lamination and m4 transformer lamination offered by jaas steel industries vadodara gujarat.

In order to gain full advantage from a laminated core the laminations must be insulated from one another.

The simplest way to do this is to specify a surface insulation on the raw material.

From thin 4 to 6 mil laminations to orthosil squared hysteresis loop silicon iron alloys the current product line.

Small hysteresis area resulting in low power loss per cycle low core loss and high permeability.

Design your ideal low loss transformer with our high quality strip wound cores or switch to the latest in folded core technology with advanced grain oriented and laser scribed silicon steel.

Steel cores or laminations can usually be removed from the protective atmosphere at 600 700 f 325 375 c without ill effect.

The qualities of the carlite 3 coating are best maintained or enhanced when stress relief annealing is conducted in an atmosphere that is neutral or slightly oxidizing to iron.

Material used is fully processed non oriented silicon steel with a coating on both sides.

Electrical steel is usually manufactured in cold rolled strips less than 2 mm thick.